- English

- Esperanto

- беларускі

- Hrvatski

- ქართული

- Монгол хэл

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Română

- Srpski језик

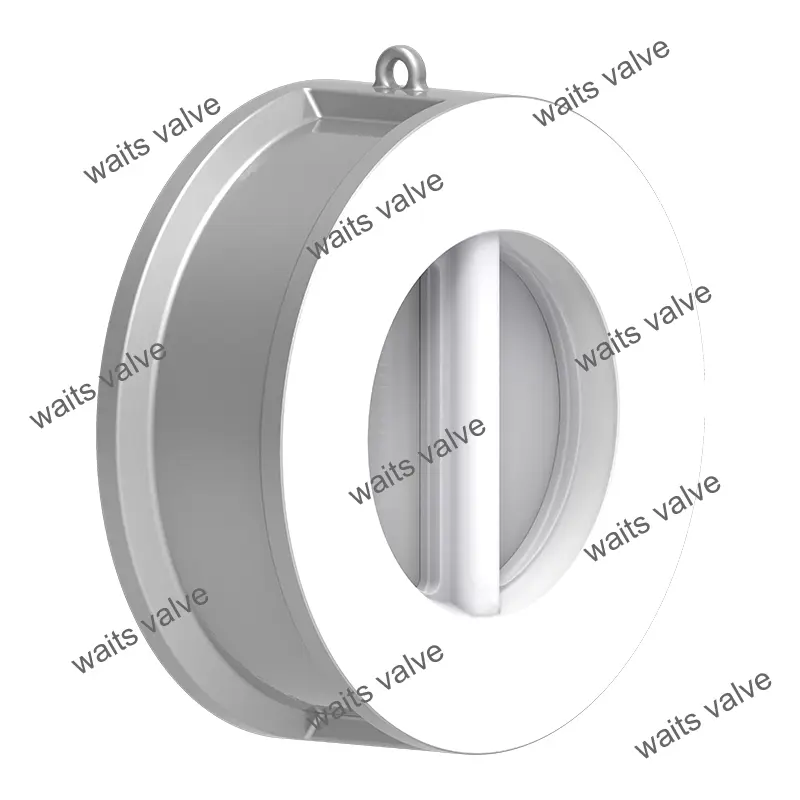

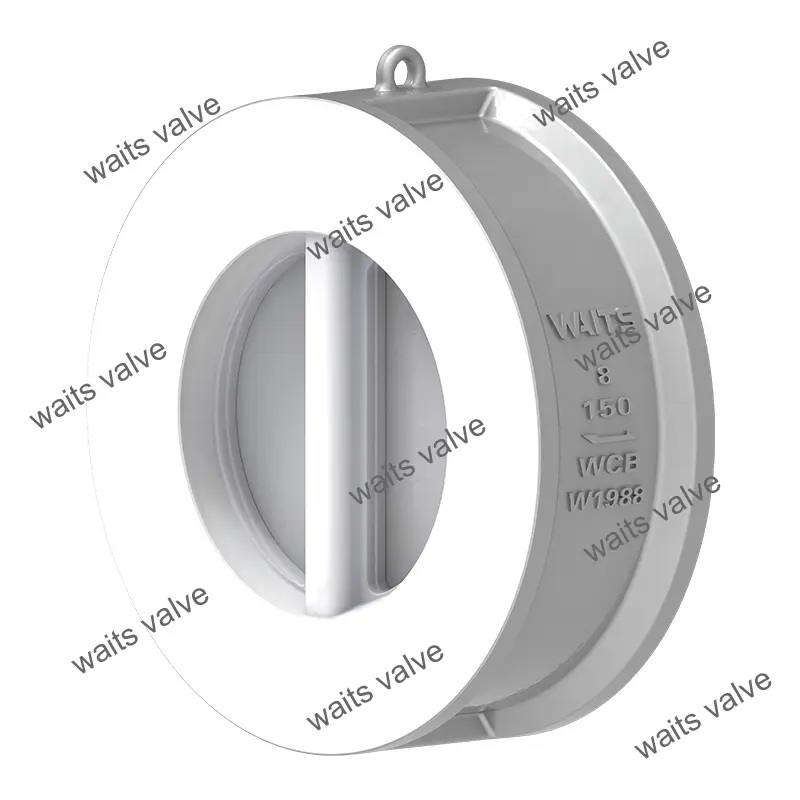

Ptfe Lined Wafer Reprehendo CYMBALON

Waits valvae PTFE Lined Wafer Reprehendo CYMBALE features ROSIUS repugnant, High Quality PTFFE Lining et Pacto Design pro Reliable Backflow praeventionis! Expectat valvae adhaeret transparent et pragmaticam Morbi cursus sapien, scilicet listing sex sumptus components, comprehendo casting, dispensando, inspectionem et aliis feodis.

Mitte Inquisitionem

Facta in Wits Valvum Factory in Sina, PTTFE Lined Wafer reprehendo valvae prohibet media backflow per compositum de fluoroplastic lining et reprehendo machinationes (ut CYMBALI DISCTUS, diaphragmata, fontes, etc.). Et core pluma est quod intus de valvae corpus et signantes superficiem sunt iactaret fluoroplastic segregare media ex metallum partes. Hae valvulae apta Pipeline systems ut deferat altus corrosi, princeps castitatis vel facile contaminari media et late in eget, pharmaceutical, electronic, environmental tutela et alia industries.

Omnes nostri valvulae sunt finguntur cum PFA Linings, quae compatitur cum maxime mordax et toxicus chemicals. Non possunt omnes esse ad temperaturis usque ad CCCXCII ° F.

Nostrum reprehendo valvulae sunt in varietate processum lineae et saepe solebat:

Ponere stabilis caput pressura ad sentinam exitus

Ne uber batch contaminari

Ptfe Lined Wafer Reprehendo CYMBALE providet simplex NITROGENIUM Blanketing Imperium

Nos sperabo possumus invenire ius valvae pro application.

| Exsequendam signa, Ptfe Lined Wafer Reprehendo CYMBALON | |

| Design Signa | API 6D / API594 / BS1868 |

| LABIUM Latin | Asme B16.5 / ASME B16.47-A / B / EN1092-1 / II |

| Iunctio modi | Wafer, FF, RF |

| Testis et acceptatio | DXCVIII ignis, en12266 |

| Longitudo | API6D / Asme B16.10 / En558 |

| Pressura et temperatus ratings | Asme B16.34 |

| Fireproof test | / |

| Low Leakage Signa | ISO 15848-1, API DCXXII |

| Anti-corrosio consilio | Nace Mr MDCCV |

| Applicationem-PTFE Lined Wafer Reprehendo CYMBALON | |

| Magnitudo | NPS II "~ XII NPS" DN50 ~ DN300 |

| Pressura range | Cl150 ~ Cl150 Pn10 pn16 |

| Temperature range | PTFE-L ° C + CLXXX ° C |

| Application range | Apta aquam, vapor oleum, nitric acidum, acetic acidum, fortis oxidizing media et alia media. |

| Valvae corpus | Dimittings: A105, A182 F304, F304L, F316, F316L, F51, F53, B148, A350 LF2, LF3, LF5, Monel, Ptfe-LF5 Castings: A216 WCB, cf3, CF8, cf3m, cf8m, 4a, 5a, c95800, LCB, LC, LC2, Ptfe-LcB, Lc2, LC2, Ptfe-LcB, Lc2, LC2, Ptfe-LcB, Lc2, LC2, Ptfe-LcB, Lcc, LC2, Ptfe-LcB, Lcb, LC2, Ptfe-LcB, Lcc, LC2, Ptfe-LcB, Lc2, LC2, Ptfe-LcB, Lc2, LC2, Ptfe-LcB, Lc2, LC2, Ptfe-LcB, Lc2, LC2, Ptfe-LcB, Lcb, LC2, Ptfe-LcB, Lc2: |

| CYMBALON | Metallum, Ptfe-Lined |

| Virga | PTFE (F4) et Graphite |

Product Features

1.Wafer Type Design: Flat extremis pro installation inter duorum pipeline flanges, secured per seras (no welding vel additional flange accessiones requiritur).

2.working principle:

Deinceps fluxus: Medium pressura tellure in disco aperto.

Reverse fluunt: Disc clauserit automatice, cum PTFE signa superficies ne backflo

Productum commoda

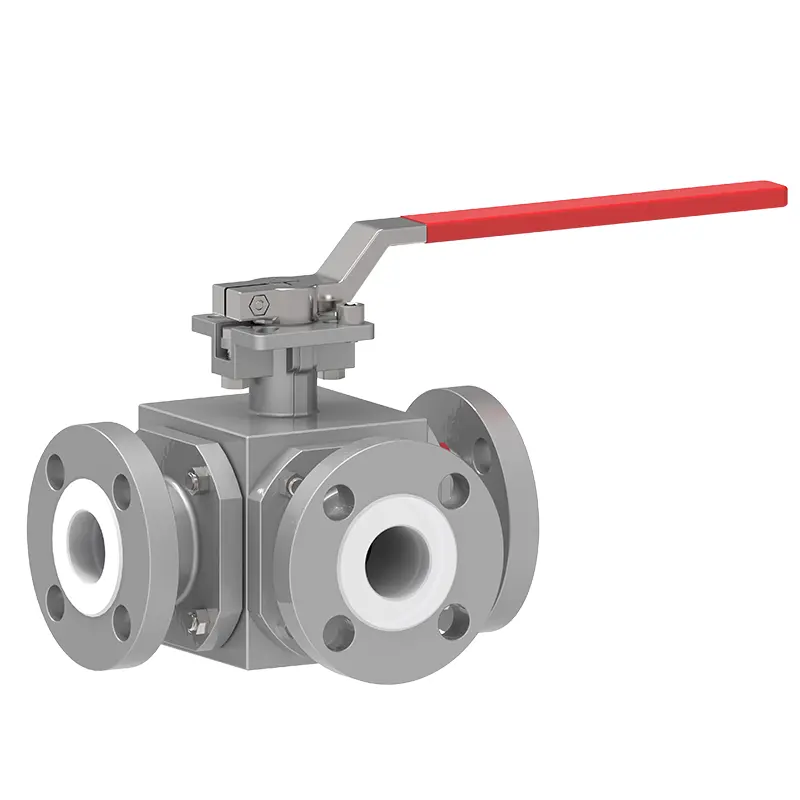

1.No separate Flannges requiritur, reducing materiam usus et pretium comparari fulsit types.

2.Simply Discopia ad sustentationem sine motabilibus fistularum, bonum spatium coactus areas (E.G., dense pipelines facis).

3.Short pervideo distantiam, idoneam ad altum fluunt, humilis viscosity media (E.G., aqua, solvents).